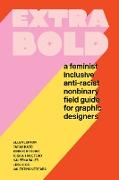

Model for integrating energy relevant criteria into factory layout planning

BücherAngebote / Angebote:

Due to shortage and rising price of energy, energy efficiency becomes a worldwide hot issue and also a significant challenge for factories. It can not only reduce company costs, but also make a great contribute to the environmental protection. Therefore, it is necessary to take the energy efficiency as a key criterion into consideration in the early planning phase. However, this issue was often ignored in the process of factory planning.

A new three-stage factory planning model including: (1). energy recovery network generation, (2). layout alternative generation and (3). layout alternative evaluation and selection, is proposed in this dissertation. In this model, an energy recovery network is firstly built to reuse process heat with the purpose of reducing energy consumption. Afterwards, in the stage of layout alternative generation, energy loss during pipes, transport performance and space requirement are simultaneously considered to generate suitable layout alternatives. In order to solve the multi-objective layout planning problem, a hybrid multi-objective optimization algorithm, which integrates NSGA-II with local search, is developed. Finally, a set of optimal solutions, which includes all possible best solutions, is found. Decision makers can choose the best layout alternative according to the practical situation and industrial preference of consumer.

As a multi-attribute decision making (MADM) problem, the evaluation and selection of layout alternatives are often difficult and time consuming since the criteria generally has different units and conflicting features. Therefore, at the stage of layout alternative evaluation and selection, a MADM approach is proposed to solve evaluation and selection problem with considering both traditional layout criteria and energy relevant criteria. This approach incorporates the advantages of fuzzy analytic hierarchy process (Fuzzy- AHP) and technique for order preference by similarity to ideal solution (TOPSIS). Besides, sensitivity analysis for both decision weights and product demand are performed, which helps the decision maker to make their decisions more rationally. Finally, the best layout alternative is found.

The proposed factory planning model can be adopted by the energy intensive companies such as aluminum alloy wheel companies or paint department. It provides a new choice for factory designer to consider the energy relevant criteria at the beginning of the planning phase.

Folgt in ca. 2-3 Arbeitstagen